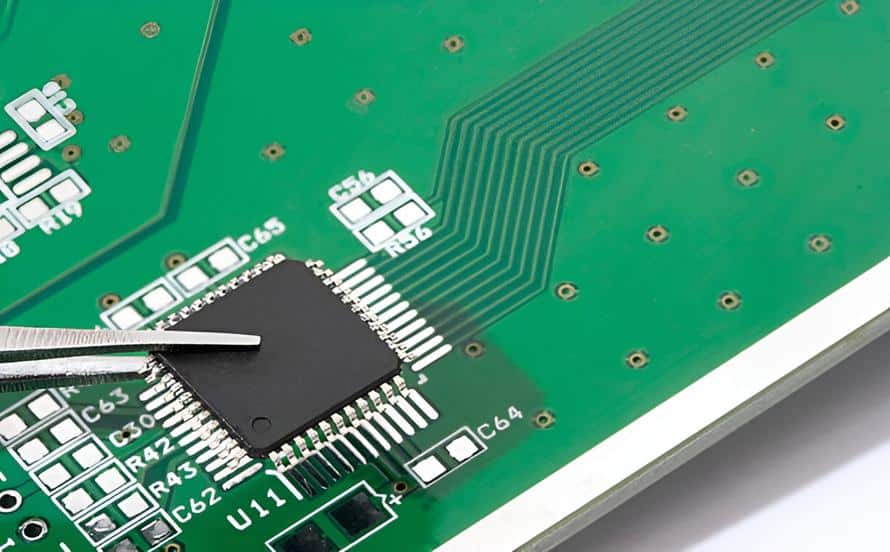

Double sided PCB assembly refers to the process of manufacturing printed circuit boards that have conductive copper layers on both the top and bottom sides. Unlike single-sided PCBs, where components and traces are only on one side, double sided PCBs allow components to be mounted on both surfaces, connected through vias. This design increases the circuit’s density and makes it possible to create more complex, compact, and reliable electronic devices.

The use of double sided PCB assembly has become a standard in electronics manufacturing due to its balance of functionality, cost, and space efficiency. It bridges the gap between simple single-sided boards and complex multilayer designs, making it suitable for a wide variety of applications across industries.

Benefits of Double Sided PCB Assembly

One of the key advantages of double sided PCB assembly is the increased circuit density it provides. By using both sides of the board, designers can place more components in a smaller space without compromising performance. This allows manufacturers to build compact devices with advanced functionality.

Another benefit is cost-effectiveness. While slightly more expensive than single-sided PCBs, double sided PCBs are much more affordable than multilayer alternatives. They provide the perfect middle ground for projects that require more complexity without the added cost of high-layer-count boards.

Double sided PCB assembly also enhances flexibility in design. Components can be strategically placed on both sides, and the use of vias ensures seamless connections between layers. This design freedom makes it easier to implement complex circuits without requiring additional board layers.

Applications of Double Sided PCB Assembly

Double sided PCB assembly is widely used across numerous industries because of its versatility. Consumer electronics such as televisions, smartphones, audio systems, and household appliances rely on these boards for compact and efficient circuitry.

In the automotive sector, double sided PCBs are used in lighting systems, dashboard displays, power supplies, and control modules. Industrial equipment also benefits from these boards in control panels, power converters, and motor controllers.

Medical devices often incorporate double sided PCB assembly for applications such as diagnostic equipment, monitoring systems, and handheld medical instruments. The combination of reliability and cost-effectiveness makes these boards ideal for the healthcare sector.

Telecommunication systems also depend heavily on double sided PCBs. From routers to communication devices, the ability to integrate multiple components in limited space is essential for achieving performance goals in networking.

Challenges in Double Sided PCB Assembly

While double sided PCBs offer many advantages, they also pose challenges during the assembly process. Soldering components on both sides of the board can be more complex, requiring advanced techniques such as wave soldering or selective soldering for through-hole components, and reflow soldering for surface-mount devices.

Thermal management is another challenge. With components mounted on both sides, heat dissipation can become difficult if not properly managed. Designers must account for heat flow and ensure that the board materials and layouts can handle the thermal load.

Inspection and testing also require precision. Automated Optical Inspection (AOI) and other advanced testing methods are necessary to ensure that both sides of the board meet quality standards. A defect on one side may compromise the functionality of the entire circuit.

Why Double Sided PCB Assembly Is Growing in Demand

The increasing demand for smaller, faster, and more reliable electronics continues to drive the growth of double sided PCB assembly. As consumer and industrial devices shrink in size but grow in functionality, the need for boards that balance complexity and affordability is greater than ever.

Additionally, advancements in manufacturing technologies such as automated pick-and-place machines and improved soldering techniques have made double sided PCB assembly more efficient and accessible. This enables manufacturers to produce boards at scale while maintaining consistent quality.

Future of Double Sided PCB Assembly

Looking ahead, double sided PCB assembly will remain a vital part of the electronics industry. While multilayer and advanced PCBs will continue to grow, double sided boards will serve as the reliable workhorse for countless applications. Their cost-effective design, flexibility, and performance make them indispensable for industries that require efficiency without excessive complexity.

As electronics continue to evolve, double sided PCBs will likely integrate with new materials, advanced heat dissipation techniques, and even hybrid manufacturing methods. This ensures they will continue to support the demands of future technology.

Conclusion

Double sided PCB assembly plays a central role in modern electronics manufacturing by offering a balance of affordability, design flexibility, and circuit density. From consumer gadgets to industrial systems, this assembly type enables engineers to create reliable and compact devices that power daily life.

For businesses looking to streamline production and ensure top-quality results, partnering with experts who specialize in PCB assembly service is essential. The right partner can provide the technology, expertise, and reliability required to deliver consistent performance in every board.

Angela Spearman is a journalist at EzineMark who enjoys writing about the latest trending technology and business news.