Ensuring food safety is continuous and involves several parties: from harvesting to manufacturing, transportation, preservation, completion of orders, and food handling.

Foodstuffs might go through dozens of processes in different people’s hands before reaching the supermarket or grocery store. It is critical to have food safety solutions in place to preserve the quality and safety of products.

On the other hand, with more people ordering food online, all those involved throughout the supply chain have a role to play. Various variables may shorten foodstuff’s shelf life or increase the likelihood of becoming dangerous for consumption and spreading diseases.

Everyone in the distribution line of a grocery is accountable for constantly delivering healthy and good-quality food to consumers. Grocers rely on other entities for refrigeration services to gather, distribute, and provide updates on their handling and delivery processes that improve the quality of food from farmers.

Gathering and preparation

The timing of harvesting food is a crucial factor in food quality since perishable crop can begin to rot as soon as it is gathered. Environmental factors like air and warmth may affect safety, quality, and longevity. However, temperatures and the atmosphere around us can be managed in various ways to impede the degradation process.

Transportation

Food can be transported for several days or weeks by road, sea, or air, and grocery stores depend on the transportation company to maintain an uninterrupted network of temperature assurance. Appropriate shipping procedures encourage ventilation and load locking to reduce excessive motion when transporting long distances. Temperature monitoring and awareness of cargo surroundings are requirements for food shipments. It includes various chilled temperature zones in a single consignment of mixed items.

Modern refrigeration systems are cloud-based due to the need to maintain goods at designated temperature levels in real time. Daydots labeling system can assist in tracking and reporting data.

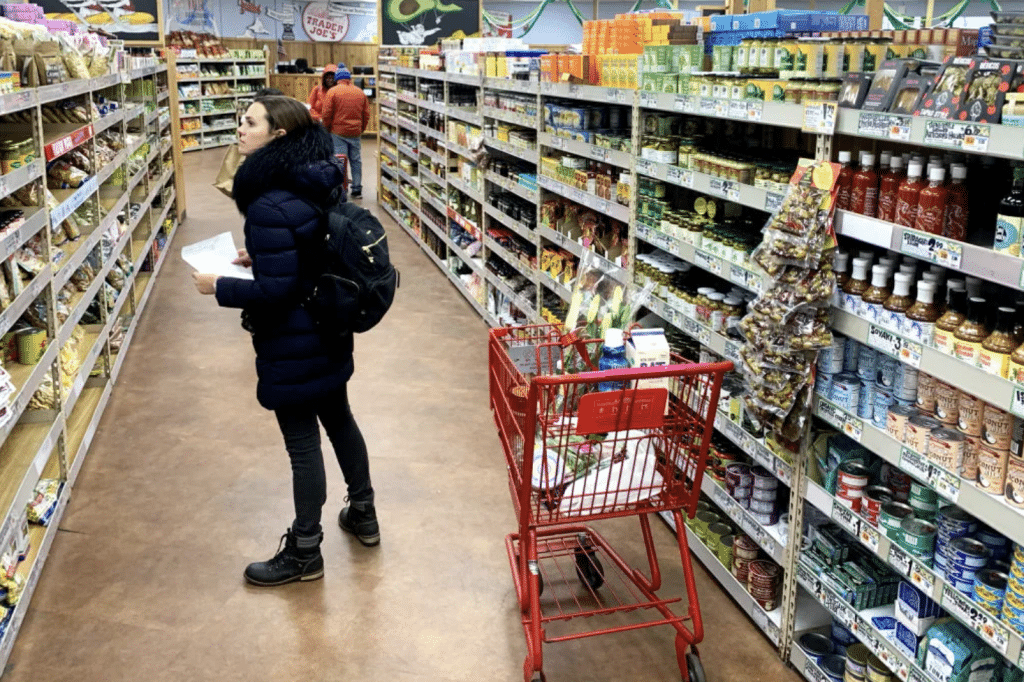

At the Supermarket or Grocery Shop

Food vendors are responsible for maintaining food safety and freshness, starting with unloading perishables at retailers. The first step is reviewing temperatures and travel records, followed by the rapid storage of perishable products in specialized refrigerators or freezers with control systems that assist merchants in enhancing food quality while in storage.

Food poisoning is brought on by consuming improperly handled, preserved, or cooked food. Therefore, storage systems must be able to manage shifts in inventory, the pressures that accompany them, and changing demand for refrigeration. In addition, it is essential to optimize processes for order processing, customer pickups, and package delivery.

Food Vendors Have a Role to Play

Food safety programs may fall apart if personnel are not dedicated to maintaining food hygiene and quality. The food business has seen a reasonable number of instances when leadership deliberately disregards regulations and procedures about food safety. Issues can be fatal, and food vendors should not disregard food safety procedures at any point and should develop it from the highest levels downwards.

Develop a Food Safety Program

A crucial way to safeguard food safety is developing a food safety strategy. A documented food safety procedure that details the exact steps and every food vendor needs measures to ensure safe food. Involving an expert in formulating your business policies and procedures ensures compliance with industry requirements.

Having knowledgeable employees is essential for mitigating food safety risks. Basic cleanliness, proper handling of food, and appropriate preparation or manufacturing methods should all be included in food safety education. Employees must know possible risks related to particular foods to know how to handle them.

Besides training personnel on food safety practices, there must be an open communication channel where staff can give feedback and ask questions. It will guarantee that any potential issues are swiftly recognized and resolved.

The Right Packaging and Storage

Packing and storage methods can compromise the nutritional value and hygiene of foods. Food packaging is the art of maintaining products in good condition and attractive to the buyer. Daydots provide a safe technique for labeling foodstuffs according to industry standards.

Clean up Equipment

Cleaning is the first step in combating foodborne diseases. To prevent illnesses, it’s important to regularly wash your hands properly, maintain your kitchen cleanliness, and prepare your food at the right heat. Keeping things clean and sanitary is essential for food retailers. Any area you expose your food to must be cleaned and sanitized regularly.

Washing is the initial phase in the procedure, which entails clearing the entire surface of all particles, pollutants, and dirt. Both hot water and an industrial disinfecting agent are commonly used to accomplish this. After cleaning the surfaces, you can sanitize the place to eliminate micro-organisms.

Pest Control

Production and storage spaces must practice the right pest control to guarantee that pests don’t get into or contaminate foodstuffs. It entails taking the right measures in facilities to eliminate and prevent organisms. It starts by being aware of the existing environment, as warehouses may offer water, food, warmth, and protection from predators. All of these things may create the perfect environment for reproduction.

To assist in stopping the spread of infectious diseases or contaminants, every possible cause of exposure needs controlling. A pest control service provider can help when moving into a new place or tackling an infestation at a food store. In some jurisdictions, it is a requirement for food vendors to do pest control frequently.

Sanitize Food Handling Areas

The traditional sanitizing procedure is to combine the right supplies, if desired and have the required contact period. After applying the products, ensure it remains on the surface after application. Then, you must clean the surfaces thoroughly with water before they come to touch with food. Although most people use their visual or smell to confirm sanitation actions, there are other more reliable methods to verify using chemical processes, if necessary.

Conclusion

When purchasing food, pick it cautiously and purchase it from recognized vendors that maintain clean and well-organized facilities. Make sure the product’s packaging is appropriate, and you should take it home right away to reduce exposure to high temperatures, which affect its safety. Ensure the dates on the product’s packaging are current, especially things that are cold or refrigerated. Ensure you always check the deadline for consuming a product.

Angela Spearman is a journalist at EzineMark who enjoys writing about the latest trending technology and business news.